In the world of packaging, selecting the right material is critical to ensuring product safety, durability, and cost-effectiveness. Among the most commonly used materials in the packaging industry are Polyethylene (PE), Polypropylene (PP), Low-Density Polyethylene (LDPE), and Chlorinated Polyethylene (CPE). Each of these materials has unique properties that make them suitable for specific applications. In this article, we will explore the differences between these materials and highlight how they are used in various packaging products, including adhesive bags, poly mailers, and ziplock bags.

Polyethylene (PE)

Polyethylene (PE) is one of the most widely used plastics globally. It is a thermoplastic polymer made from the polymerization of ethylene. PE is known for its strength, flexibility, and resistance to moisture, making it a popular choice for packaging.

Characteristics:

PE is durable, lightweight, and resistant to chemicals and moisture. It has excellent sealing properties and is typically used in a variety of applications ranging from food packaging to protective wraps.

Packaging Applications:

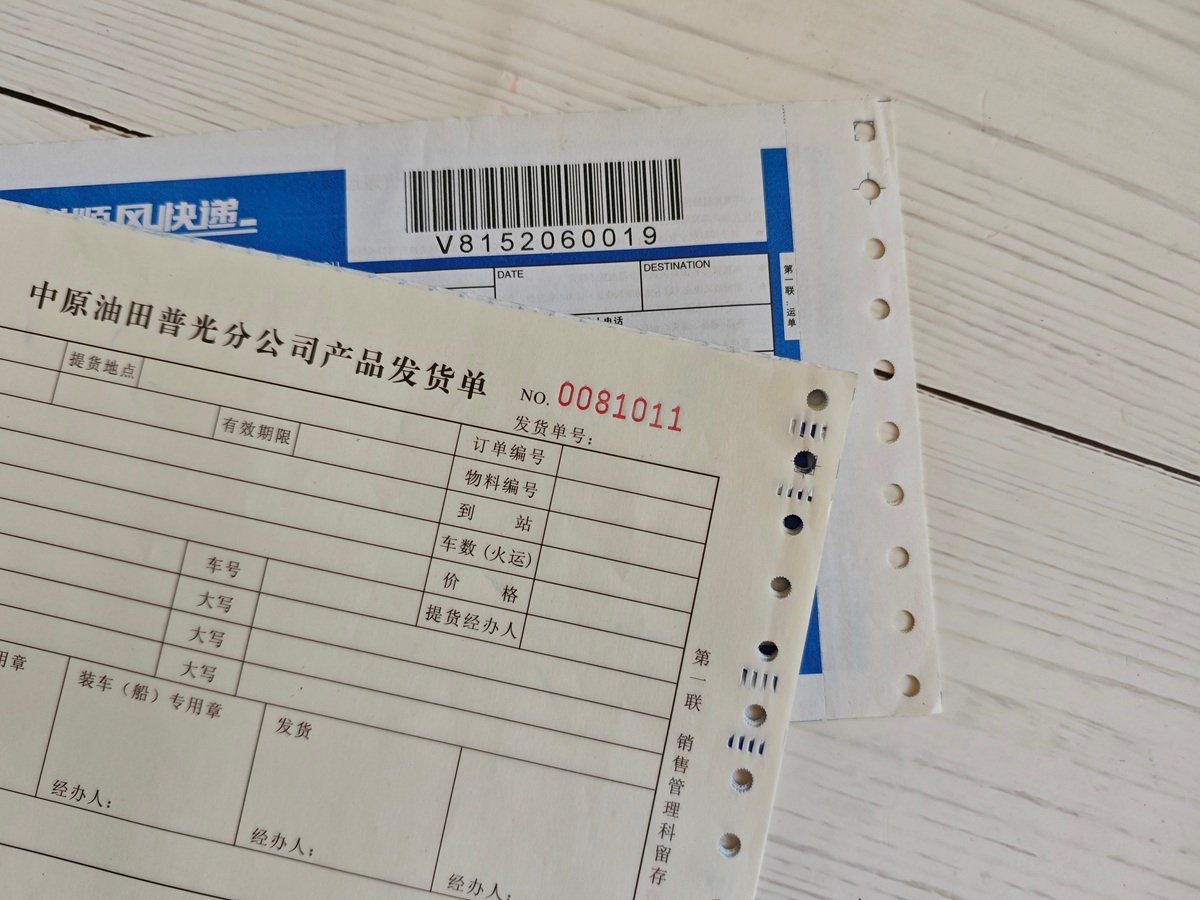

In the context of packaging, PE is commonly used for adhesive bags (such as the “Packing List Enclosed” bags) and plastic mailers. These bags are ideal for shipping important documents, small products, and items that require a sealed, moisture-resistant enclosure.

Polypropylene (PP)

Polypropylene (PP) is another thermoplastic polymer, but unlike PE, it is made from the polymerization of propylene monomers. PP is known for its stiffness and higher melting point, which provides additional strength in certain applications.

Characteristics:

PP is lightweight, resistant to wear and tear, and offers superior chemical resistance. It also has a higher tensile strength compared to PE, making it suitable for packaging that requires more structural integrity.

Packaging Applications:

PP is commonly used in manufacturing adhesive bags similar to those made from PE. These bags are often used for shipping and storing documents or smaller products that need to be securely sealed and protected from moisture.

Low-Density Polyethylene (LDPE)

LDPE is a variant of polyethylene that features a lower density than standard PE. This results in a material that is more flexible, transparent, and softer to the touch.

Characteristics:

LDPE is known for its flexibility, low-temperature performance, and ability to stretch without tearing. It is also less rigid and more resistant to cracking under low temperatures compared to other forms of polyethylene.

Packaging Applications:

LDPE is commonly used in the production of poly mailers (also known as “shipping bags” or “poly mailer bags”). These bags are ideal for e-commerce shipments, especially for clothing, textiles, and other non-fragile items. Their flexibility allows them to conform to the contents, while still providing protection against moisture and minor impacts.

Chlorinated Polyethylene (CPE)

CPE is a polymer derived from the chlorination of polyethylene. This material offers enhanced properties such as increased chemical resistance and improved mechanical strength, making it suitable for more specialized applications.

Characteristics:

CPE is highly resistant to aging, wear, and chemicals, and offers better flexibility than other types of polyethylene when exposed to extreme conditions. It also has superior weathering resistance, making it ideal for outdoor use.

Packaging Applications:

CPE is often used for making ziplock bags, which are ideal for both packaging and organizing small items. The combination of CPE’s flexibility and resistance to moisture makes it an excellent choice for reusable and resealable bags in a variety of industries.

Conclusion

In conclusion, PE, PP, LDPE, and CPE each have distinct characteristics that make them suitable for specific packaging needs. From PE and PP adhesive bags used for shipping documents and small items, to LDPE poly mailers perfect for e-commerce shipping, and CPE ziplock bags ideal for organization and storage, these materials play a crucial role in the packaging industry. By understanding the properties and applications of these polymers, businesses can make informed choices about which material to use for their packaging needs, ensuring the best protection and performance for their products.