Discover how to test the load bearing capacity of courier bags to ensure they can handle heavy shipments. Practical testing tips to guarantee secure deliveries.

Introduction

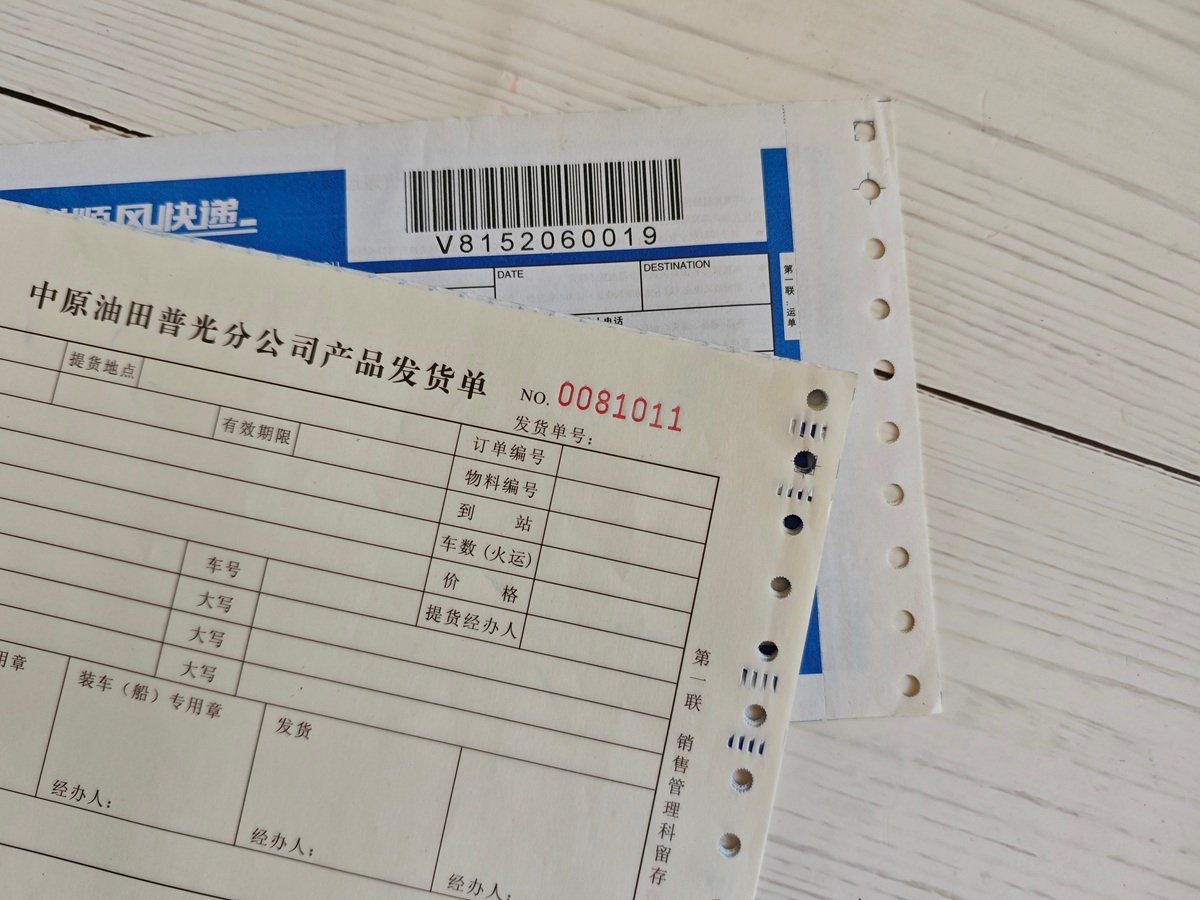

Courier bags must not only protect against water and tearing, but also bear the weight of the items inside. The load bearing capacity of a courier bag measures how much weight it can carry without breaking. In this article, we’ll guide you through easy methods to test load capacity and why it matters for reliable shipping.

Why Load Capacity Matters

Overloaded or poorly designed courier bags can tear during transport, causing product damage, customer dissatisfaction, and added costs. Ensuring the right load capacity helps companies prevent losses and maintain a professional shipping image.

How to Test the Load Capacity of a Courier Bag

1. Standard Load Test

- Place a standard weight inside the courier bag according to its size (e.g., 2kg, 5kg, 10kg).

- Lift and carry the bag, simulating real shipping movements.

- Check if the bag stretches, tears, or if the sealing area loosens.

2. Incremental Load Test

- Gradually add weight into the bag until it reaches its limit.

- Record the maximum weight the bag can hold without damage.

3. Swing and Shake Test

- After loading, swing the bag gently or shake it up and down.

- This simulates the movements during transport and checks if the bag can sustain dynamic stresses.

What to Expect in a High-Quality Bag

- Handles the recommended weight without stretching or tearing.

- Sealing areas stay strong even under heavy loads.

- Minimal deformation even under repeated movements.

Conclusion

Testing the load capacity of courier bags ensures that your packaging solutions can handle real-world demands. Choose strong, reliable bags to safeguard your products and build customer confidence in your service.