Discover why your thermal labels may not be printing dark enough. Learn about common causes like print head issues, speed settings, and label quality, and how to fix them for better printing results.

Introduction

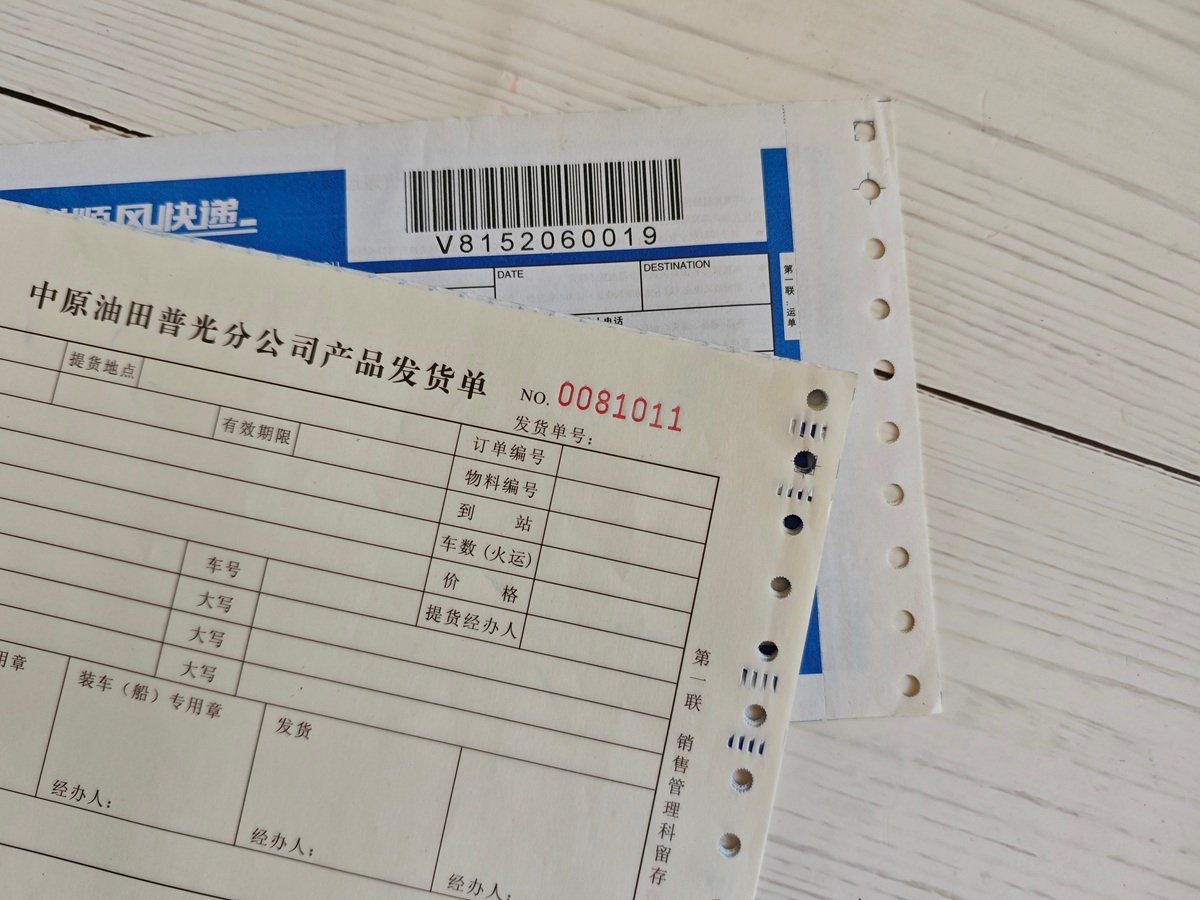

Thermal labels are an essential part of packaging, shipping, and inventory management. However, it can be frustrating when your thermal labels don’t print as dark or clear as expected. Whether you’re using direct thermal or thermal transfer printing, a poor print quality can lead to scannability issues, label unreadability, and wasted time. In this article, we’ll explore the common causes of light print on thermal labels and offer practical solutions to ensure your labels print with the desired quality.

Common Causes of Light Printing on Thermal Labels

Understanding why your thermal labels are not printing dark enough is the first step toward fixing the problem. Here are the most common causes:

1. Incorrect Printer Temperature Settings

Thermal printers rely on heat to transfer ink or create an image on the label. If the temperature settings of your printer are too low, the print head won’t generate enough heat to produce a dark and clear print.

Solution:

Ensure that the temperature setting on your thermal printer matches the material of the labels you’re using. Typically, printers have temperature controls that need to be adjusted based on the type of label (such as direct thermal or thermal transfer). Test your printer with different temperature settings to find the optimal one for dark and clear prints.

2. High Print Speed

While high-speed printing can increase efficiency, it may reduce the quality of the print. When printing too quickly, the print head may not have enough time to transfer sufficient heat to the label, resulting in faint or unclear prints.

Solution:

Try slowing down the printing speed. Most thermal printers allow you to adjust the print speed in the settings. Lowering the speed can give the print head more time to apply heat to the label, producing better quality and darker prints.

3. Low-Quality Thermal Labels

The quality of the thermal labels you use plays a huge role in print quality. Low-quality thermal labels, especially those made from subpar materials, may not absorb heat well, causing the printed image to appear light or incomplete.

Solution:

Choose high-quality thermal labels from trusted manufacturers. Ensure the labels are compatible with your printer model and meet the required standards for your application. You may also want to test labels from different suppliers to see which produces the best results.

4. Dirty or Worn-Out Print Head

A dirty or damaged print head can cause uneven printing, leading to poor print quality. Over time, paper dust and ink residue can accumulate on the print head, blocking the transfer of heat to the label.

Solution:

Regularly clean your printer’s print head using cleaning wipes designed for thermal printers. Ensure the printer is turned off and unplugged before cleaning to avoid damage. If cleaning does not resolve the issue, the print head may be worn out and may need to be replaced.

5. Poor Label Adhesion or Backing

If you’re using two-layer thermal labels, such as those with an adhesive backing and thermal paper layer, the quality of the adhesive or backing can impact the print quality. If the backing isn’t firmly attached, or the adhesive layer causes warping, it can affect the heat transfer process.

Solution:

Make sure that the backing is properly adhered to the thermal paper. If the adhesive is causing issues, try using labels with a stronger adhesive or ensure that the labels are stored properly before use to avoid sticking or peeling.

6. Incorrect Label Thickness

If the thermal label material is too thick or too thin, the print quality may suffer. Thicker labels can absorb too much heat, resulting in light prints, while thinner labels may not hold the image well.

Solution:

Adjust your printer’s settings to accommodate the thickness of the labels. Also, ensure that you’re using labels that are appropriate for your printing process. For example, direct thermal labels are typically thinner than thermal transfer labels, which can handle a broader range of thicknesses.

7. Driver or Software Issues

Sometimes, printer drivers or software settings may not be properly configured, leading to poor printing results. If the driver isn’t optimized for the type of labels you’re using, or if the resolution settings are incorrect, the print quality can be compromised.

Solution:

Ensure that your printer driver and software are up to date and correctly configured. Adjust the print resolution to ensure the highest possible print quality. Higher resolution settings typically result in better-quality prints, but they may slow down the printing speed

Conclusion

If your thermal labels aren’t printing dark enough, the issue could be related to a variety of factors, including print head temperature, print speed, label quality, or printer maintenance. By following the solutions outlined above, you can identify and resolve the root cause of the problem, ensuring your labels print clearly and accurately.

Regularly maintaining your printer, selecting high-quality labels, and adjusting printer settings will help you achieve the best printing results. Whether you’re printing for logistics, shipping, or inventory management, high-quality thermal labels are crucial for business success and operational efficiency.

Take Action: Improve Your Thermal Label Printing Today

If you’re experiencing light print on your thermal labels, follow these steps to improve print quality. Don’t let poor print quality affect your business operations—adjust your settings, maintain your printer, and choose the right materials for consistent, clear prints.